.jpg)

.jpg)

Dewazakura Sake Brewery was founded in 1892 by Seijiro Nakano, whose head family owned Kuma Masamune Sake Brewery. There were three Nakano family's Sake Brewery until Showa period. Dewazakura Sake Brewery is located in Tendo City, Yamagata Prefecture, a small town of 60,000 residents located 300 kilometers north of Tokyo. Situated in the Yamagata Basin and surrounded by high mountains, Tendo City is hot in summer, often exceeding 35 degrees Celsius, and in the winter can receive considerable snowfall, often exceeding one meter in depth. These natural features, including the climate, have made the region a major production center of rice, fruits and other products. Using this great rice, we have been making sake by hand. For example, we use small tanks enough to handle manually. It makes precision temperature control possible, which in turn allows us to brew high-quality sake in small quantities.

Dewazakura began to market Ginjo* Sake, named Oka Ginjo, in 1980, the first attempt of its kind for sake breweries. Back then, Ginjo was mainly made for completion and the word "Ginjo" was rarely known; only those involved in sake brewing were familiar with the word. However, we wanted everyone to enjoy Ginjo so we decided to sell Ginjo for an affordable price for the public. Oka Ginjo was well received, triggering the so-called "Ginjo boom."

* Premium grade classification of sake with a rice polish ratio of 60% or less; usually light and fragrant

In 2008, Oka Ginjo topped the list for 12 consecutive years for the Ginjo category in Jizake Ninki Meigara Ranking, an authoritative guidebook on the most popular local sake published by Fullnet Corp. In 2011, Berry Bros. & Rudd, Britain's oldest wine merchant and a supplier of wine to the British Royal Family, started to handle Oka Ginjo as the first Japanese sake in its lineup, making the Ginjo available to customers all over the world. The rich scent of Oka Ginjo even attracted the attention of the cosmetics industry. Oka Ginjo played a role in the development of the scent of a new product of SK-II, a cosmetic brand belonging to P&G Max Factor.

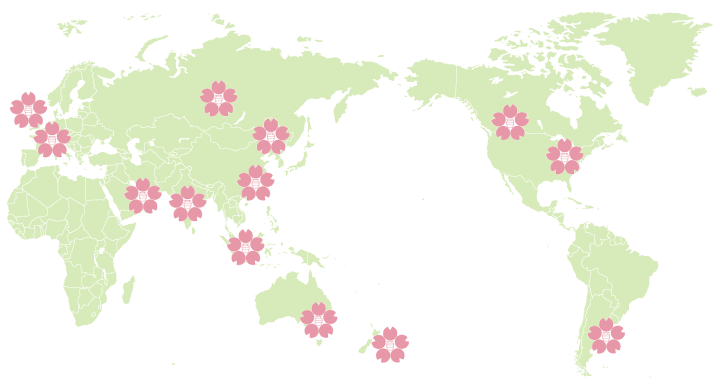

We started exports of Sake in 1997. We now export to over 30 countries, spreading the joy of drinking Ginjo to people in many parts of the world. We are trying to make "Ginjo" a familiar word worldwide through the export of Ginjo, which we believe constitutes a valuable part of Japanese culture.

| Company name | DEWAZAKURA SAKE BREWERY CO.,LTD |

| address | Head office & the main brewery (Tendo Brewery) 1-4-6, Hitoichimachi, Tendo-City, Yamagata-Pref., 994-0044, Japan Yamagata Brewery 1-1-60, Uwamachi, Yamagata-City, Yamagata-Pref., 990-2483, Japan |

| Foundation Year | 1892 (Meiji 25th) |

| Representative | Masumi Nakano, President |

| TEL / FAX | TEL. +81 23-653-5121 / FAX. +81 23-653-0600 |

| info@chiyokotobuki.com | |

| Company Business | Production and sales of sake |

Sake brewing begins with polishing brown rice. Getting good steamed rice is a first step toward brewing good sake.

The outer part of a grain has much proteins, lipids and minerals, which cause negative aromas and flavors. Thus, the outer part must be milled away to brew clear tasted sake. Usually, this process is done by contractors but we polish rice with our own polishing machines. A polishing ratio shows the degree to which the rice has been polished. Our average polishing ratio is 50%.

.png)

.png)

Rice is washed to remove the rice bran and soaked to attain a certain water content deemed optimum for steaming that particular rice. The soaking time is controlled strictly on the second time scale. Although conditions, such as air temperatures, water temperatures and qualities of rice, are different every day, we find the best solution with a huge number of recorded data and skilled techniques.

.png)

Rice is steamed with Koshiki, which is a traditional steamer. Ideal steamed rice should be firm on the outside and soft on the inside. The steamed rice is carried to Koji-muro, which is a Koji making room, and fermentation tanks.

.png)

.png)

After cooling down, the steamed rice is used for making Koji, Shubo and Moromi. There is a general phrase expressed as "Koji comes first, Moto(Shubo) comes second, and Tsukuri (Moromi) comes third" so these processes are very important.

Koji is an essential thing to make sake, soy sauce, miso and mirin. Rice koji is steamed rice onto which koji mold has been cultivated. The role of rice koji is to release enzymes that break down starch into glucose. Rice koji can be made by machine but we have been making it by hand. Especially, when rice koji of Daiginjo is made, it's divided into small wooden boxes to control temperature strictly.

.png)

.png)

Shubo is made by mixing steamed rice, rice koji, water and yeast in a small tank. As the meaning of Shubo represents the mother of sake, the number of yeast increases inside shubo. There are various kind of sake yeast, which affect the taste and the aroma of sake. One of the biggest characteristic of Dewazakura is fluty aroma called Ginjo-ka coming from the yeast.

.png)

.png)

Shubo is transferred to a large tank, where steamed rice, rice koji and water are gradually added three times. This mixture is called Moromi and this process is called Sandan jikomi. Sandan jikomi is done over a four-day period so as not dilute the acidic environment. By promoting a fermentation slowly at low temperature, clear tasted sake can be brewed.

.png)

.png)

When a fermentation is completed, it is pressed to separate the newly created sake from the solid remains of the fermented rice called Sake-kasu. Especially, when Moromi of Daiginjo is pressed, the drops of sake are collected in bottles without any pressure to the moromi. This special way is called Fukuro-tsuri or Tobin-gakoi.

.png)

.png)