ABOUT US

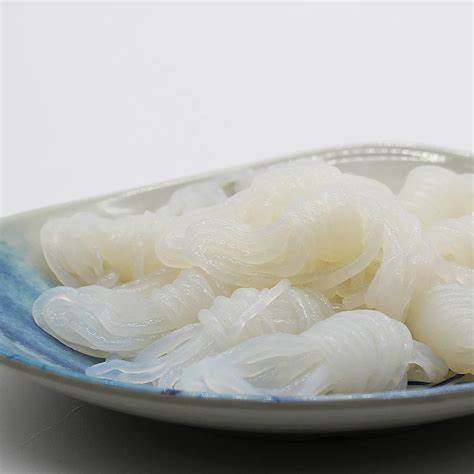

People and nature. Japan and the world. Tradition and innovation. Good taste and quality. We will fuse two parallel and sometimes contradictory values to create new food. In addition to new proposals that can meet your needs, we also put more sincerity and passion than ever before into manufacturing products. In planning and development, we use unprecedented imagination and ideas while exploring the infinite possibilities of konjac. AIA Foods aims to be a food company that can contribute to the lives of people living in the future and the activities of the earth through healthy and sustainable manufacturing, focusing on the traditional food "konjac". A Foods is creating products that expand the possibilities of konjac. In addition to conventional konjac, we will continue to develop a wide range of products such as desserts and plant-based products. Konjac" has been called "sand grated" since ancient times, and is a traditional food that has been popular in Japan for a long time due to the wisdom and ingenuity of our predecessors over a long history.

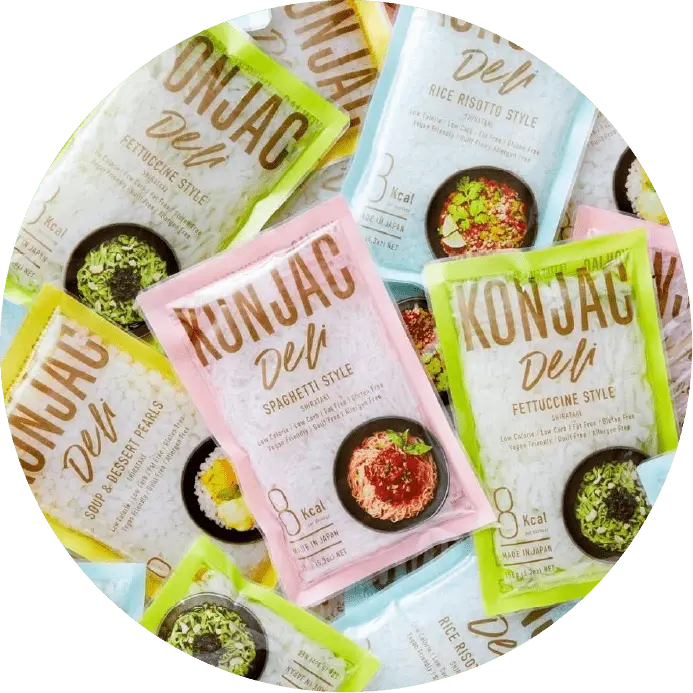

OUR PRODUCT

BENEFITS

Low-Calorie:

Both konjac cake and noodles are extremely low in calories. Shirataki noodles, for example, contain about 10-20 calories per serving (100 grams), while konjac cake is similarly low in caloric content. This makes them an excellent option for anyone looking to reduce their calorie intake or manage their...

Lowers Cholesterol:

Glucomannan has been shown to reduce cholesterol levels by binding to cholesterol in the digestive tract and preventing its absorption. This can contribute to lowering total cholesterol and LDL ("bad") cholesterol levels, reducing the risk of heart disease.

High in Fiber:

Konjac products are rich in glucomannan, a type of soluble fiber that helps improve digestion. The fiber absorbs water in the digestive tract, which can help regulate bowel movements and prevent constipation