ABOUT: TAMARI SAUCE

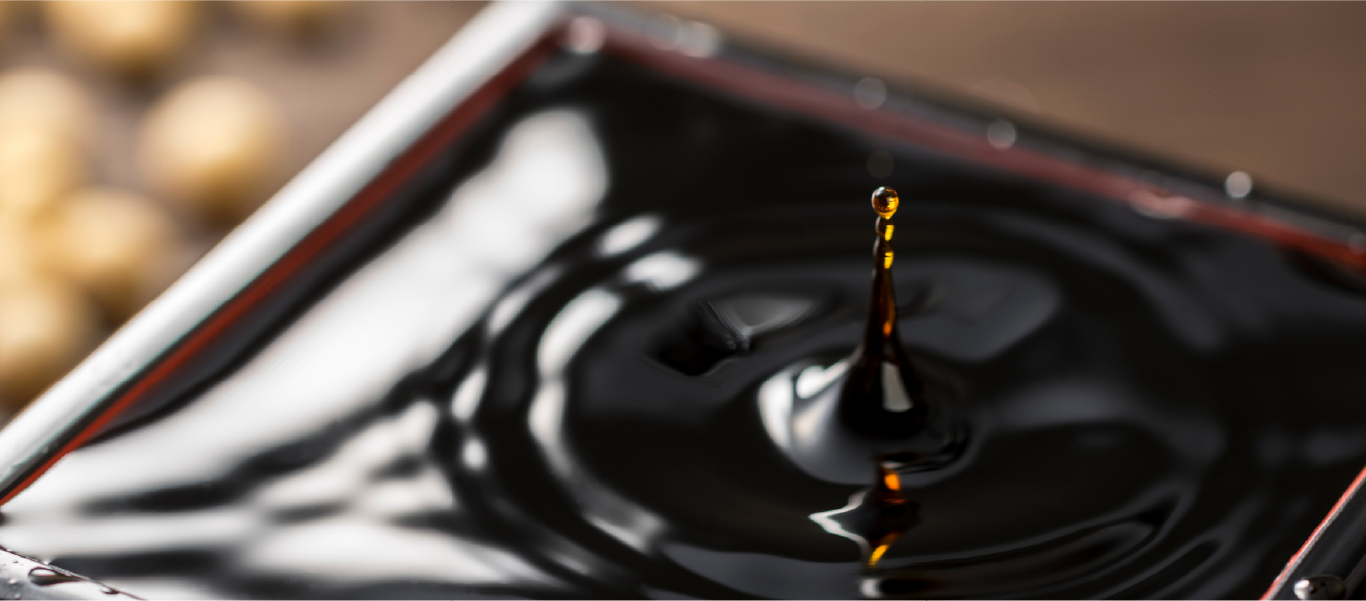

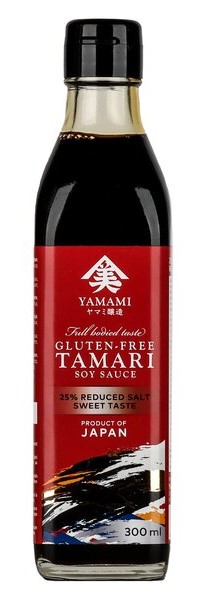

Yamami Tamari Sauce is a specific brand of tamari sauce, and it's known for being gluten-free, organic, and high-quality. The name "Yamami" itself is derived from the Japanese term for "umami," which refers to the rich, savory flavor that is one of the five basic tastes.Tamari sauce is a type of soy sauce, but with a few key differences that make it stand out. Originating from Japan, tamari is traditionally made as a byproduct of miso paste production. While both tamari and regular soy sauce are made from fermented soybeans, tamari tends to have a richer, smoother, and less salty flavor.Yamami Tamari Sauce is known for its rich umami flavor and gluten-free properties, as it contains little to no wheat. The traditional method used by Yamami Jyozo ensures that each drop of tamari is packed with flavor and quality.

OUR PRODUCT

BENEFITS OF TAMARI SAUCE

Gluten-Free

Tamari is often naturally gluten-free, making it an excellent alternative for people with gluten sensitivities or celiac disease. Unlike traditional soy sauce, which typically contains wheat, tamari is made without it. This makes tamari a safe choice for those following a gluten-free diet.

Natural Fermentation:

Tamari undergoes a natural fermentation process, which means it can contain beneficial probiotics. These probiotics support gut health and digestion by promoting a healthy balance of bacteria in the digestive system. The fermentation process also breaks down the proteins in soy, making it easier for your body to absorb certain...

Lower Sodium Options:

Although tamari is generally salty, some brands offer low-sodium varieties. If you're watching your salt intake, these options can provide the same depth of flavor with less sodium, which can be beneficial for heart health and managing blood pressure.