ABOUT: KOKUMOTUSU GRAIN VINEGAR

Grain vinegar, also known as distilled white vinegar, is a type of vinegar that is made from the fermentation of grain alcohol. This process involves the conversion of the grain alcohol into acetic acid, which gives vinegar its characteristic sour taste and strong odor. Unlike other types of vinegar, grain vinegar is clear and colorless, making it a popular choice for culinary and household uses. Grain vinegar is known for its versatility and is commonly used in cooking, baking, salad dressings, and pickling. It is also a popular ingredient in household cleaning solutions due to its acidic properties, which make it an effective disinfectant and sanitizer. In addition to its culinary and household uses, grain vinegar is also utilized in various industrial applications, such as in the production of cosmetics, pharmaceuticals, and food preservatives.Grain vinegar is made from the fermentation of grain alcohol, while apple cider vinegar is made from the fermentation of apple cider. They differ in taste, appearance, and potential health benefits.grain vinegar is a popular choice for pickling due to its clear color and neutral flavor, which allows the natural colors and flavors of the fruits and vegetables to shine through.

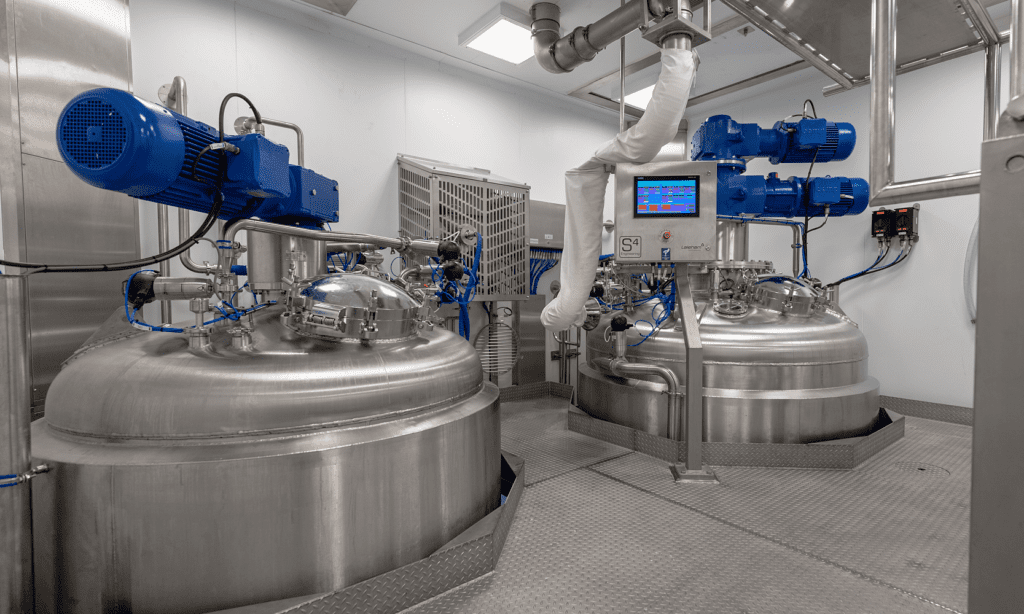

OUR PRODUCT

Weight Management:

Grain vinegar, particularly rice vinegar, has been suggested to help with weight management. The acetic acid may help reduce fat storage, improve metabolism, and promote feelings of fullness. Some studies show that regular consumption of vinegar can help people feel fuller and reduce overall calorie intake.

Helps with Detoxification:

Vinegar is sometimes thought to help the body with detoxification. It can support liver function by helping the body eliminate toxins more efficiently, though these claims need more scientific backing. Nonetheless, the acetic acid in vinegar may support the body’s natural detox processes.

Antibacterial and Antifungal Properties:

The acidic nature of grain vinegar gives it antibacterial and antifungal properties. It can be used as a natural disinfectant for cleaning surfaces, and some people use it topically (diluted) for minor skin conditions or to treat dandruff. However, it’s not a substitute for medical treatment.